Refit project for the "ARCTIC SUNRISE'

Over an intense nine-month period, Royal Niestern Sander Shipyard firmly took on the Arctic Sunrise in a refit project. During the extensive overhaul, nearly all of the accommodation and work areas of this Greenpeace vessel were renewed, granting the vessel at least another 15 years of service. Director Bart Volgers looks back on this successful project.

Conversion icebreaker 'SERKEBORG' into diving support vessel

The offshore support vessel Serkeborg, sailing in the Wagenborg Offshore fleet, will play a crucial role during subsea diving- and maintenance work at an oil terminal. For this long term contract, Wagenborg Offshore commissioned Royal Niestern Sander to convert Serkeborg into a so called diving support vessel. At the yard, Marc van Dijk gives an insight into this project.

General cargo vessels 'ARTICA 1' and 'ARTICA 2' converted for polar waters

The increasing activity in Russian Arctic waters has been noted by Royal Niestern Sander. The yard was approached to carry out a complicated conversion of two dry cargo vessels. The ‘Arctica 1’ and ‘Arctica 2’ were to be converted for use in extreme winter temperatures and conditions. Thanks to the shipyard’s extensive knowledge in the area of ice-strengthened ships – as was previously apparent from the series construction of ice-strengthened dry cargo ships and the specialist icebreakers ‘Sanaborg’ and ‘Serkeborg’ – Niestern Sander was successful in winning this particular conversion project.

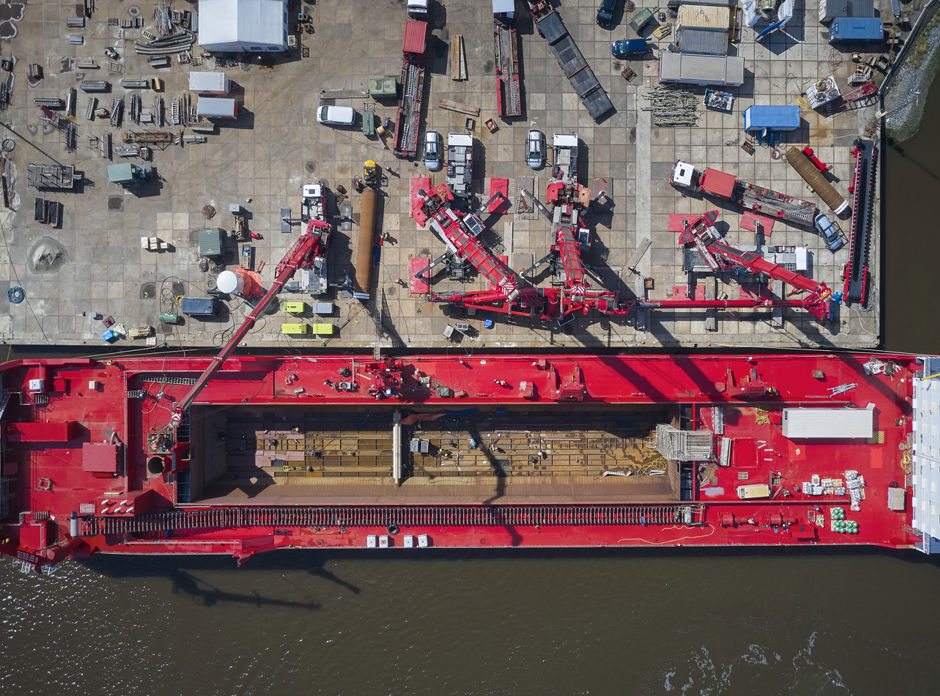

'YED PRIOR': from container ship to gravel hopper dredger

The first contact with Royal Niestern Sander for this special conversion was made by the end of 2019. Mr. D.W. den Herder, owner of Maritiem BV, approached Niestern Sander with a request to make a quotation for the conversion of the Yed Prior, then a container ship called GERD, to a gravel hopper dredger for Spaansen. Originally, Spaansen had nothing to do with shipping, but the company now has its own fleet.

Fully electric utility vessel 'PW18'

Shipyard Royal Niestern Sander – a wholly owned subsidiary of the Wagenborg Group – has delivered the first Dutch fully electric utility vessel to the Province of Groningen. The new green vessel, the PW 18, was christened in March 2019 by Fleur Gräper-van Koolwijk, Executive Councillor for the Province of Groningen. After the christening ceremony, we spoke to the shipyard’s Managing Director Jan Doorduin and Fleur Gräper-van Koolwijk about this sustainable ship.

Survey ROV support vessel 'GEO RANGER'

Shipyard Royal Niestern Sander has built a new shallow-water survey ROV support vessel called Geo Ranger. It has been developed with the crew and the survey equipment in mind. It is equipped with smart on-board technology, comprising various different sensors and a plug-and-play system for additional, project-specific customer equipment. With its focus on improved workability, durability and flexibility, the Geo Ranger may well set a new standard for survey vessels.